Product

| Inverter Condensing Smoke Tube Packaged Boiler [HMP-EX] | |

|

Inverter fan and sequential water supplier with perfect proportional control

Characteristic

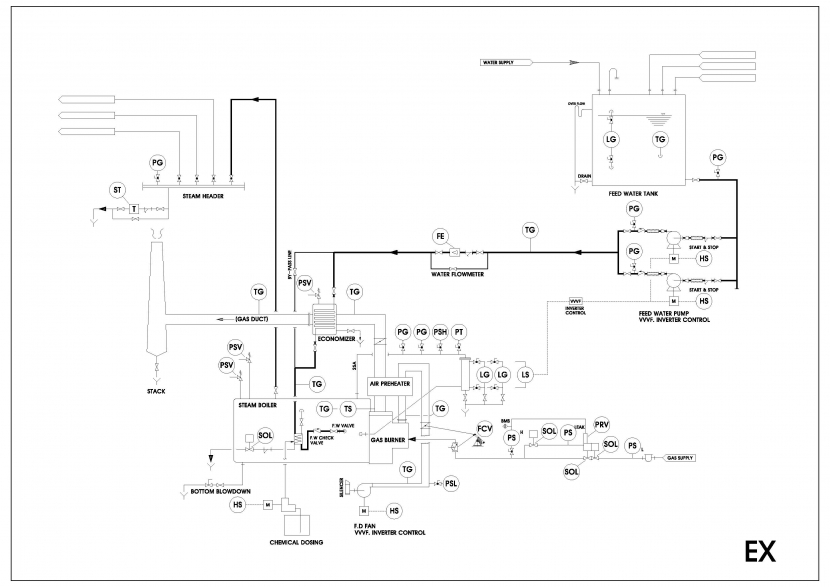

● 100% automatic control available by simply touching on the screen. ● Intelligent functions setting of operating conditions, checking of the operation history. remote control. etc. ● Inverter saving the use of electricity by up to 49%. ● No additional space needed to install the air pre-heater and economizer. ● Heat pipe - type air pre-heater recovering the heat in the exhaust gas, pre-heating combustion air and increasing combustion efficiency. ● Economizer equipped with an STS316 spiral tube recovering the condensed latent heat in the exhaust gas, Increasing the water temperature and heightening the thermal efficiency of the boiler system. |

|

ITEM EX-010 EX-015 EX-020 EX-025 EX-030 EX-035 EX-040 EX-045 EX-050 EX-060 EX-070 EX-080 EX-100 EX-120 EX-150 BODY RATED EVAPORATION kg/hr 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000 6,000 7,000 8,000 10,000 12,000 15,000 HEAT OUTPUT MWh 0.7 1.0 1.4 1.7 2.1 2.4 2.8 3.1 3.5 4.2 4.9 5.6 7.0 8.4 10.5 HOT WATER Gcal/hr 0.6 1 1.2 1.5 2 2.3 2.5 3 3.5 4 4.5 5-5.5 6-6.5 7-8 10 DESIGN

PRESSUREMPa 1.0 (1.2, 1.4, 1.6) EFFICIENCY % 99 ~ 100% HEATING

SURFACEm2 16 25.1 29.4 33.4 39.5 46.3 56.7 67 74.9 86.1 99 110 135.7 172 204 WEIGHT kg 6,800 8,600 9,200 10,600 11,800 12,500 14,300 15,700 17,400 18,300 23,900 33,400 38,300 44,500 54,100 CONTAINED

WATER (FULL)kg 1,620 2,400 2,800 3,060 3,750 4,110 6,550 6,710 7,630 8,010 9,540 13,090 15,090 21,880 25,690 CONTRAINED

WATER (NORMAL)kg 1,250 1,800 2,110 2,320 2,900 3,200 5,290 5,430 6,190 6,260 7,420 9,610 12,080 17,580 20,720 FUEL

CONSUMPTIONOIL (DIESEL) kg/hr 63 94 126 157 189 220 252 283 315 378 441 504 630 755 944 LNG Nm3/hr 65 97 130 162 195 227 259 292 324 389 454 519 648 778 973 LPG + AIR Nm3/hr 45 67 89 112 134 157 179 201 224 268 313 358 447 537 671 LPG Nm3/hr 29 43 58 72 87 101 116 130 145 174 203 232 289 347 434 kg/hr 54 81 108 135 162 189 216 243 270 324 378 432 540 648 811 BURNER COMBUSTION

CONTROL

SYSTEMPROPORTIONAL CONTROL TYPE GAS TYPE IGNITION

SYSTEMDIRECT PILOT AIR

PRETYPE HEAT PIPE TYPE MODEL EX-010J EX-015J EX-020J EX-025J EX-030J EX-035J EX-040J EX-045J EX-050J EX-060J EX-070J EX-080J EX-100J EX-120J EX-150J WEIGHT kg 401 516 645 719 820 1011 1149 1149 1350 1504 1786 2037 2367 2742 3412 ECONOMIZER FEED WATER EX-010E EX-015E EX-020E EX-025E EX-030E EX-035E EX-040E EX-045E EX-050E EX-060E EX-070E EX-080E EX-100E EX-120E EX-150E HOT WATER EX-010-EDB EX-015EDB EX-020EDB EX-025EDB EX-030EDB EX-035EDB EX-040EDB EX-045EDB EX-050EDB EX-060EDB EX-070EDB EX-080EDB EX-100EDB EX-120EDB EX-150EDB POWER

CONSUMPTIONFEED WATER PUMP kWxEA 1.1 x 2 1.5 x 2 2.2 x 2 2.2 x 2 2.2 x 2 3 x 2 4 x 2 4 x 2 4 x 2 4 x 2 5.5 x 2 5.5 x 2 5.5 x 2 11 x 2 11 x 2 CIRCULTING

PUMPkW 0.4 0.4 0.4 0.75 1.5 1.5 1.5 1.5 1.5 2.2 2.2 2.2 3.7 3.7 5.5 FAN STEAM kW 3.7 5.5 7.5 11 11 11 11 15 18.5 22 30 40 45 55 75 HOT WATER kW 3.7 5.5 7.5 11 11 11 11 15 18.5 22 30 40 45 55 75 VALVE STEAM VALVE A 50A 65A 80A 100A 125A 150A 200A SAFETY VALVE A 25A 40A 40A 40A 40A 40A,25A 40A,25A 40Ax2 40Ax2 40Ax2 50A,40A 50A,40A 50Ax2 65A,50A 65Ax2 FEED WATER

VALVEA 25A 40A 50A DRAIN VALVE A 40A 50A GAS VALVE A 50A 65A 80A HOT WATER

INLET&OUTLETA 65A 80A 100A 125A 150A 200A 250A (axb) mm 255x550 255x550 340x600 340x600 340x640 350x700 425x700 425x700 450x850 450x900 450x900 600x900 600x1,000 600x1,200 750x1,200 FLUE DUCT Ømm 300 370 420 470 520 560 600 630 670 730 790 840 950 1,030 1,160 INSTALLATION

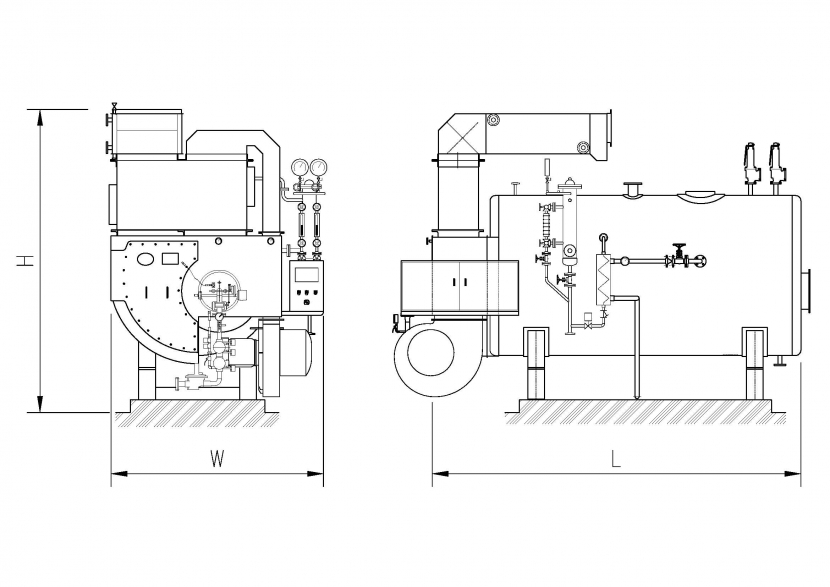

SUMMARYL mm 2,920 3,000 3,380 3,720 3,740 3,919 4,390 4,540 4,540 5,250 5,355 6,003 6,213 7,035 7,675 W mm 1,935 2,047 2,220 2,250 2,343 2,343 2,529 2,606 2,662 2,662 2,890 2,973 3,143 3,374 3,584 H mm 2,784 2,874 2,962 3,000 3,292 3,317 3,606 3,700 3,756 3,815 4,117 4,204 4,404 4,820 5,095 * Based on pressure 1.0 MPa, Feed Water Temperature 20℃, Fuel calorific value OIL(DIESEL) : 10,300 Kcal/kg, LNG : 10,000 Kcal/Nm3, LPG+AIR : 14,500 Kcal/Nm3,

LPG : 22,400 Kcal/Nm3 (12,000 Kcal/kg)

* The specification table above can be changed in order to improve performance without advance notice.