Product

| Standard – Type Smoke Tube Type Packaged Boiler [HMP-700] | |

|

High - performance boiler with a high level of thermal efficiency and reliability

Characteristic

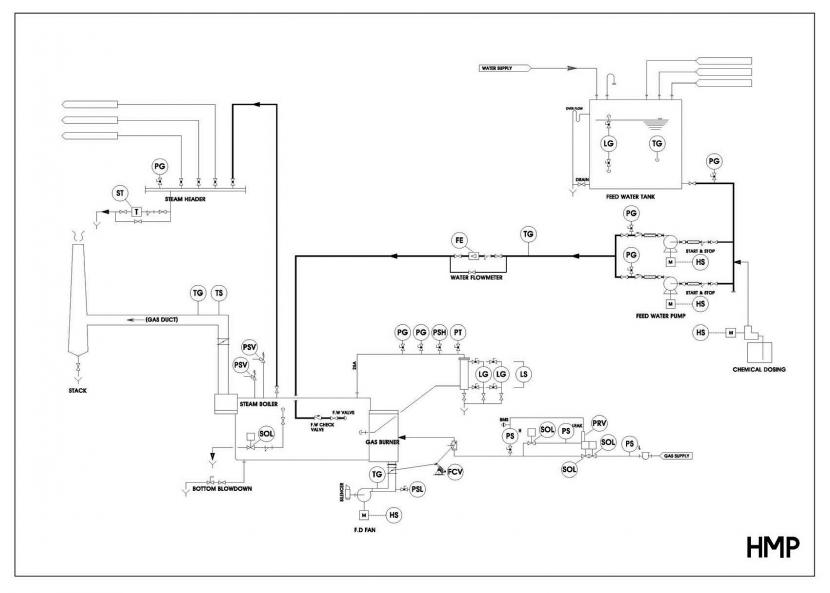

● Tubular structure with a high level of durability and heat transfer effect. ● Not susceptible to load variation / guaranteeing steam of high quality and purity. ● Easy internal external maintenance and repair. ● Easy transfer and installation / compact and sophisticated exterior. |

|

ITEM HMP-700 HMP-701 HMP-702 HMP-703 HMP-704 HMP-705 HMP-706 HMP-707 HMP-708 HMP-709 HMP-710 HMP-711 HMP-

712HMP-

714BODY RATED EVAPORATION kg/hr 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000 6,000 7,000 8,000 10,000 HOT WATER Gcal/hr 0.3 0.6 1 1.2 1.5 2 2.3 2.5 3 3.5 4 4.5 5-5.5 6-6.5 QUANTITY OF HEATX103 kcal/hr 322 643 965 1,287 1,609 1,931 2,253 2,575 2,897 3,219 3,862 4,506 5,150 6,438 HEAT OUTPUT MWh 0.3 0.7 1.0 1.4 1.7 2.1 2.4 2.8 3.1 3.5 4.2 4.9 5.6 7.0 HEATING SURFACE m2 13.6 21.3 28.8 39.4 48.1 55.7 63.1 71.9 80.1 87.6 103.3 119.2 135.6 173.3 VALVE STEAM VALVE A 50A 80A 100A 125A 150A 200A SAFETY VALVE 0.7 MPa A 25A 40A 40A 40A 50A 40A,25A 40Ax2 40Ax2 40Ax2 50A,40A 50Ax2 50Ax2 65A,40A 65Ax2 1.0 MPa A 25A 25A 40A 40A 40A 40A,25A 40A,25A 40A,25A 40Ax2 40Ax2 40Ax2 50A,40A 50A,40A 50Ax2 FEED WATER VALVE A 40A 50A DRAIN VALVE A 40A 50A WATER GAUGE L 220 L 280 L FUEL

CONSUMTIONOIL (DIESEL) kg/hr 35 71 106 142 177 212 248 283 319 354 425 496 567 708 LNG Nm3/hr 36 73 109 146 182 219 255 292 328 365 438 511 584 729 LPG+AIR Nm3/hr 25 50 75 101 126 151 176 201 226 252 302 352 402 503 LPG Nm3/hr 16 33 49 65 81 98 114 130 147 163 195 228 261 326 kg/hr 30 61 91 122 152 182 213 243 274 304 365 426 486 608 WEIGHT kg 3,800 5,700 6,600 7,600 8,400 9,600 11,000 12,100 13,000 14,000 15,700 17,000 18,700 21,500 CONTAINED WATER (FULL) kg 1,880 3,070 3,720 5,050 5,560 6,200 7,410 8,500 9,730 9,770 10,240 13,550 15,130 18,830 CONTAINED WATER (NORMAL) kg 1,470 2,450 3,040 4,100 4,450 4,980 5,960 6,830 7,740 7,860 8,100 10,820 12,100 15,240 (axb) mm 200x150 255x550 255x550 340x600 340x600 340x640 350x700 425x700 425x700 450x850 450x900 450x900 600x900 600x1,000 EXHAUST PORT m2 0.03 0.14 0.14 0.204 0.204 0.218 0.245 0.297 0.297 0.383 0.405 0.405 0.54 0.6 FLUE DUCT Ømm 210 300 370 420 470 520 560 600 630 670 730 790 840 950 INSTALLATION

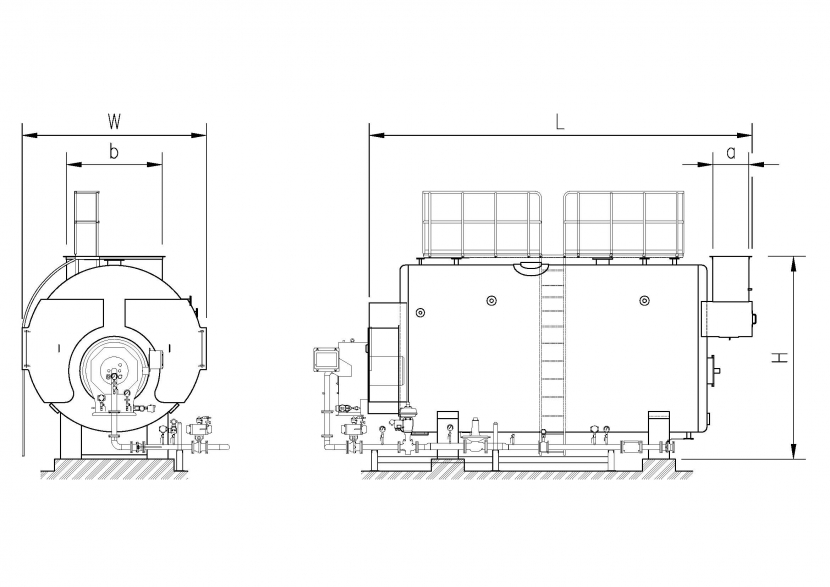

SUMMARYW mm 1,720 1,850 1,980 2,150 2,200 2,280 2,360 2,470 2,520 2,550 2,700 2,800 2,900 3,080 L mm 2,750 3,400 3,520 3,900 4,150 4,450 4,650 4,850 5,150 5,280 5,600 5,850 6,050 6,410 H mm 1,835 1,935 2,095 2,290 2,350 2,430 2,505 2,635 2,675 2,735 2,880 2,956 3,075 3,385 * Based on pressure 1.0 MPa, Feed Water Temperature 20℃, Fuel calorific value OIL(DIESEL) : 10,300 Kcal/kg, LNG : 10,000 Kcal/Nm3, LPG+AIR : 14,500 Kcal/Nm3,

LPG : 22,400 Kcal/Nm3 (12,000 Kcal/kg)* The specification table above can be changed in order to improve performance without advance notice.